Drilling with a maximum of flexibility

Drilling is the most common type of machining in the machining industry. We have taken up this topic and have put together a programme that offers the

perfect solution for many applications.

Skillyfully holed with

interchangeable inserts.

- Diameter 1 - 60 mm

- Optimum economy due to interchangeable inserts

- Can be used on all common machine types

Internal cooling

The designs with individual coolant connections are possible. This significantly increases the service life of the tool.

Maximum stability

Due to positive insert seating, even materials with high strength are drilled safely and very easily.

Easy exchange inserts

Different exchangeable inserts can be used with the same tool holder.

One for all

Different interchangeable plates can be used with the same tool holder. This shortens the set-up times enormously.

Quality

The well-known Leistritz quality enables maximum tool life and process reliability

Reconditioning

Not new, but just like new: With reconditioning in original equipment quality, we offer an absolutely economical solution.

Process Analysis

Our experts analyse your current process with you and develop the optimal tool from it.

Drills

Thanks to our many years of experience, especially in the in-house construction of machines and the manufacturing

of turbine blades, we know exactly what is important for metal cutting tools. Together with our customers, we develop individual solutions and manufacturing processes that help them optimize their manufacture, reduce production costs and thus gain a competitive advantage

Products

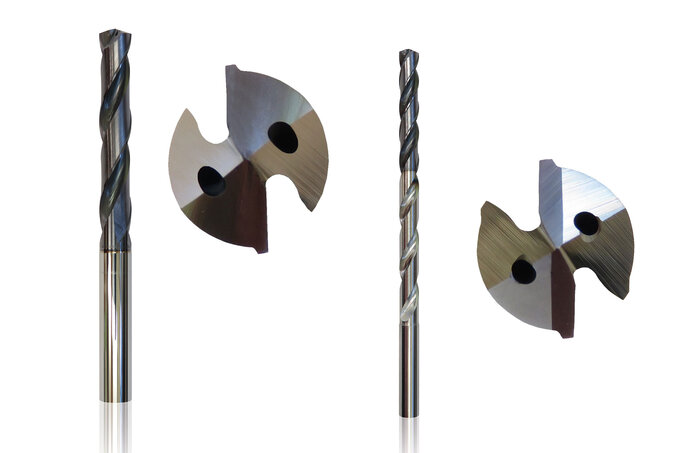

Step and Form drills

A particularly economical solution are our step and form drills, which allow you to drill

several holes with different diameters in one single process. As with all our special-purpose

tools, here too we design the cutting geometry specifically for your application!

This means time-consuming tool changes are a thing of the past, which reduces production

time and thus saves money.

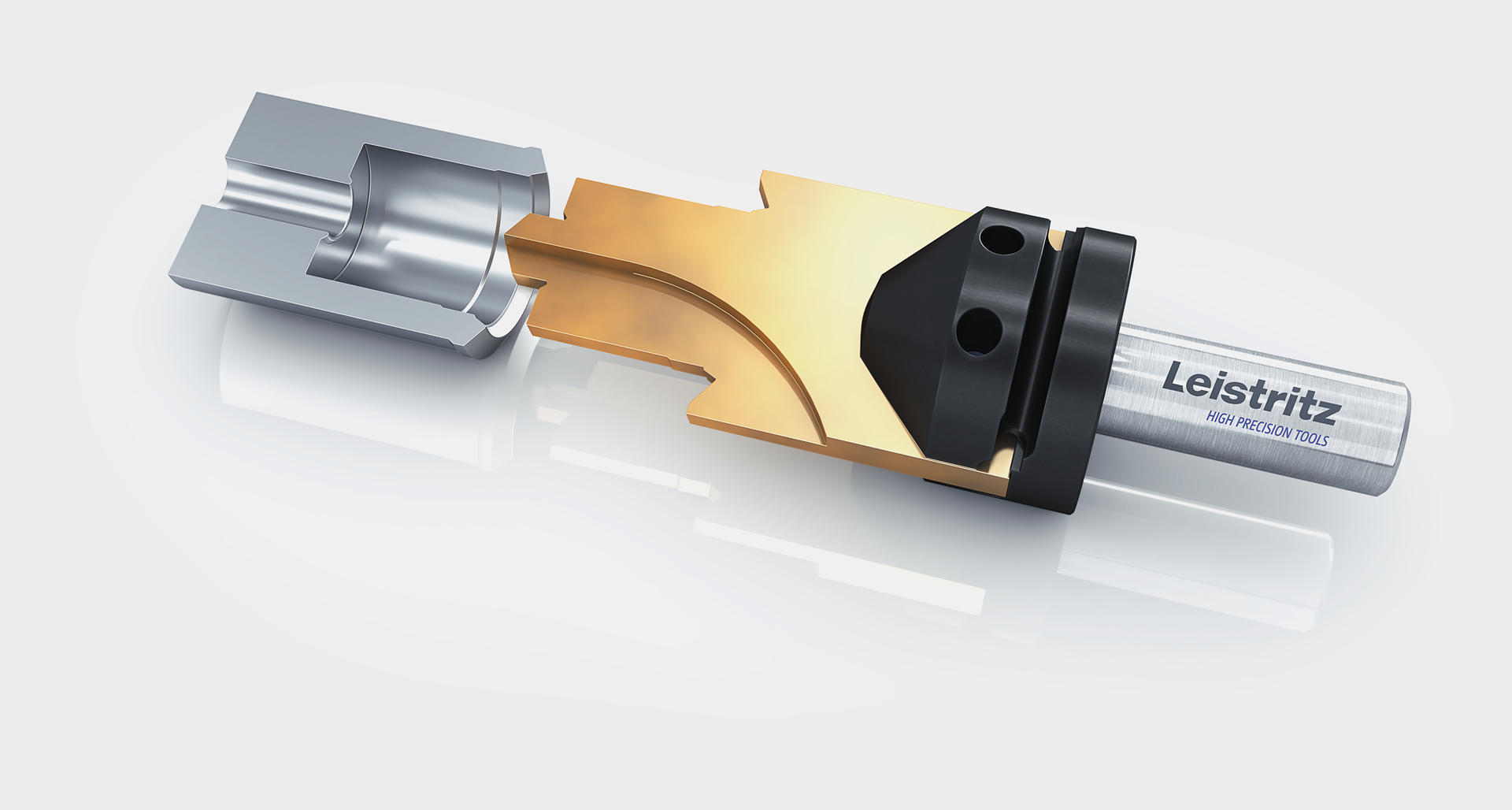

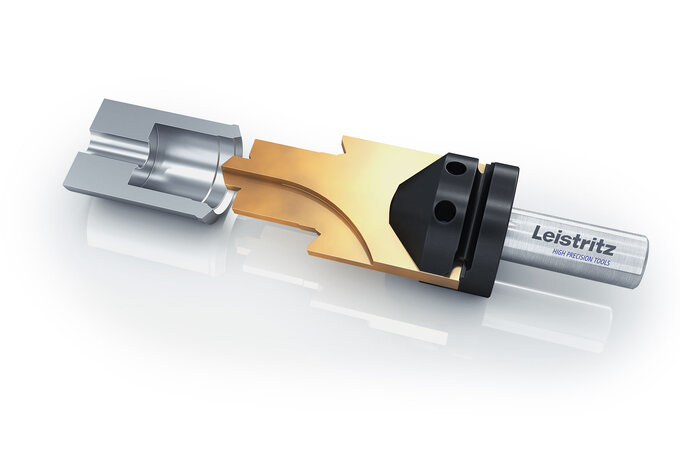

Insert Based Drilling

Drilling with a maximum in flexibility

- Diameter 1 - 60 mm

- Maximum economical due to inserts

- Usable in every common machine type

Reaming

Leistritz offers solid carbide reamers to complement the solid carbide drill programme for economical and reliable fine machining of your bores. The reamer programme includes diameters from 0.95 to 20 mm. In addition to the standard reamer NC, there are the high-performance reamers S2 and VA, which meet the highest demands on cutting speed and tool life.

Solid Carbide Drilling

The machining process includes modern solid carbide drills. Our experts use the Leistritz delivery programme in standard and customised versions.

Soon you can configure your individual tool, using our product configurator

We are here for you

You have any questions about our solutions? Your personal contact person looks forward to hear from you!

Andy Sperber

Customer Service

Leistritz Produktionstechnik GmbH

T+49 (9654) 89-283