The production of complex parts requires sophisticated tools! High process reliability, tool life and surface quality are particularly important in milling. With Leistritz solid carbide milling cutters, we have the right tool for your machining task. Special milling

cutters with short delivery times are our strength. Of course, we also offer standard end mills for roughing and finishing.

The cutter that shows teeth.

Maximum number of cutting edges for highest productivity

- Various coatings – suitable for your application

and processes - Full-range supplier – with standard and individual solutions for every application

Highest product quality

With the latest manufacturing technologies, we produce the maximum in repeat accuracy.

High economic efficiency

By using multi-edged inserts you increase the lifetime of the inserts enormously.

Maximum flexibility

The cutting edges of the profile inserts are individually adapted for your application.

Innovative mounting

The plates can be changed with maximum precision in a very short time – with only one screw.

Our Add-on for you

We will provide you with the appropriate special tools for changing the plates free of charge.

Quality

The well-known Leistritz quality enables maximum tool life and process reliability

Reconditioning

Not new, but just like new: With reconditioning in original equipment quality, we offer an absolutely economical solution.

Process Analysis

Our experts analyse your current process with you and develop the optimal tool from it.

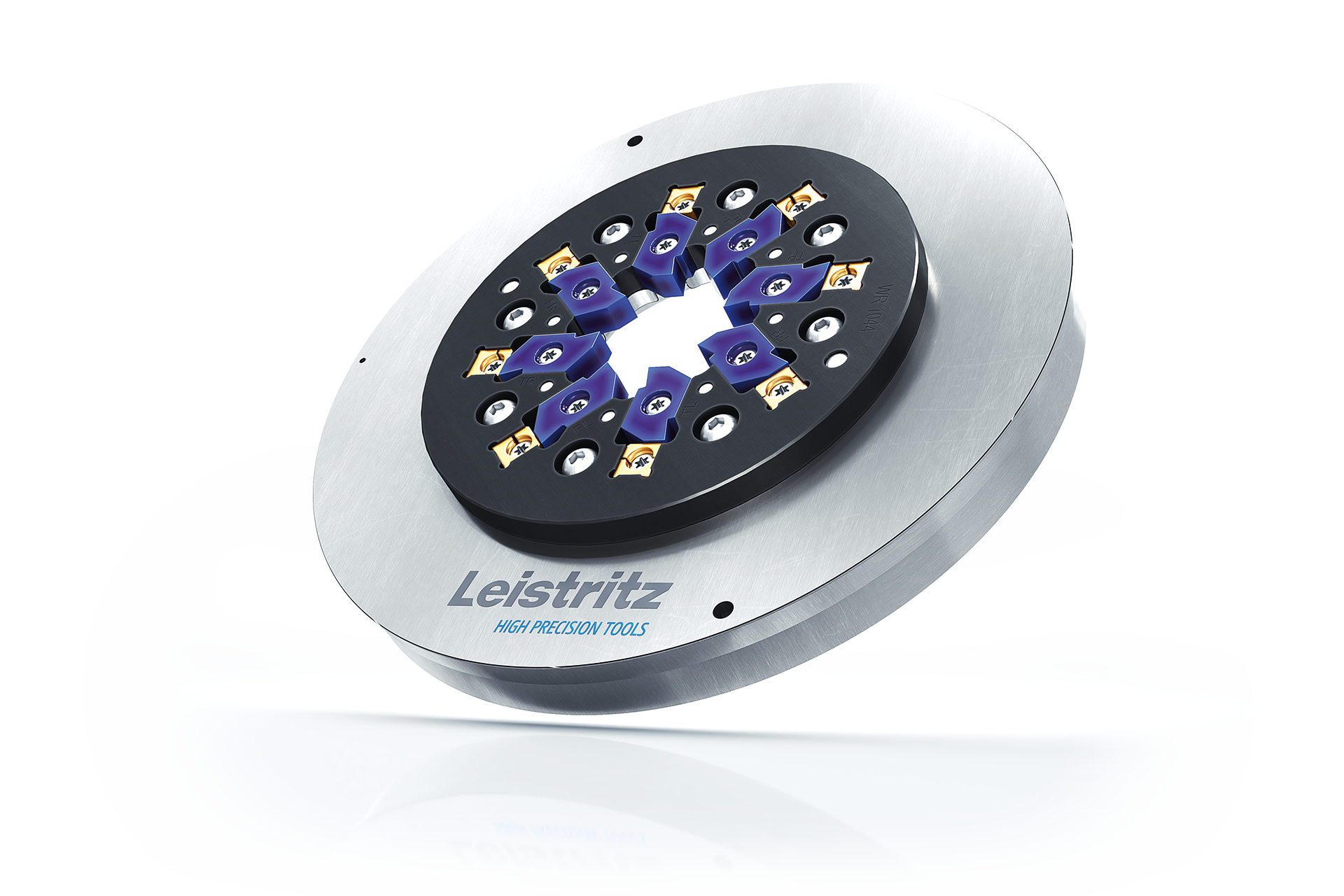

The whirlwind for profile milling.

Profile accuracy down to the μ

- For Leistritz whirling machines as well as for other

Machine tool brands – with our tools you get the

maximum out of your whirling process.

Highest material removal rate

The optimum process design of the whirling tool and machine reduce the number of number of passes required can be can be minimised.

Optimum tool design

Number of teeth, chip removal, heat management as well as insert strategy are individually adapted to your application.

Maximum tool life

Thanks to perfect geometric design and a wide range of coatings, fast wear is a thing of the past.

Regrinding service

Save time and money: The cutting edges can be reground several times.

Process reliability

Rely on consistent quality, even

after a large number of machining

operations. With Leistritz special

cutters you always produce

precisely.

Maximum tool life

Through individual coatings you

minimise wear and extend the

lifetime if the tool to maximum.

High surface quality

Optimal geometry, paired with the

best materials, provides surfaces

that are second to none.

Soon you can configure your individual tool, using our product configurator.

We are here for you

You have any questions about our solutions? Your personal contact person looks forward to hear from you!

Andy Sperber

Customer Service

Leistritz Produktionstechnik GmbH

T+49 (9654) 89-283

Sandra Kühn

Customer Service

Leistritz Produktionstechnik GmbH

T+49 (9654) 89-836