High-precision grinding of rotationally symmetrical

components is a common way of manufacturing

in many industries – both with and without a

supporting element.

Guides you through the final finish.

The art of guidance

- Diverse design competence – according to

manufacturer's specifications, customer

drawing or as a new Leistritz design

Individual Form

Mounting, stops and steps are individually designed and manufactured for your workpiece.

Precision counts

With tolerances in the μ range for steps, Leistritz work rest blades are perfectly suited for high precision applications.

Maximum lenght

Leistritz work rest blades can be produced up to a length of 3 m. This means that even long components can be ground in just one pass.

Individual Tipping

Whether carbide, PCD or ceramic – we offer the optimum equipment for every application in order to maintain the precision of your work rest blade for as long as possible.

Machine brand-independent

Leistritz work rest blades can be used on all common grinding machines. This means you are always on the safe side, even when changing machines.

Quality

The well-known Leistritz quality enables maximum tool life and process reliability

Reconditioning

Not new, but just like new: With reconditioning in original equipment quality, we offer an absolutely economical solution.

Process analysis

Our experts analyse your current process with you and develop the optimal tool from it.

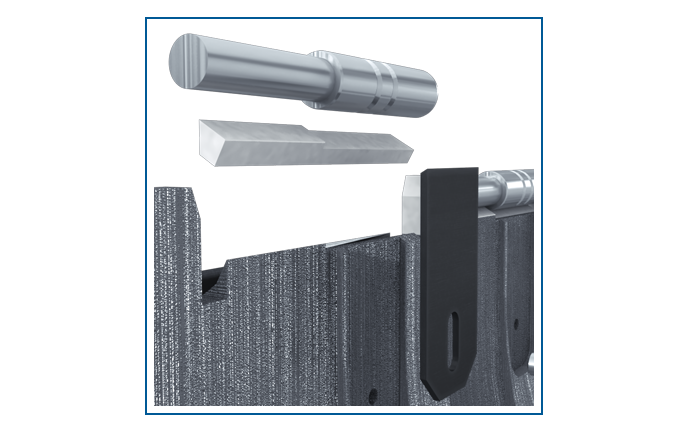

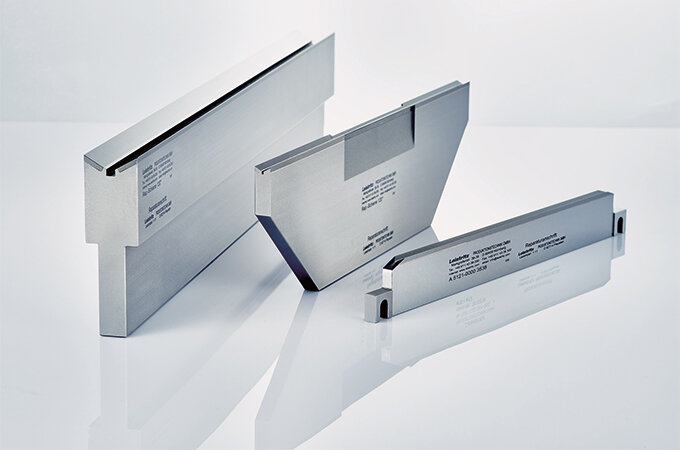

We can also produce complex indivudal shapes: Whether step work

rest blades, multi-chambers for grinding several workpieces or individual

shapes – we manufacture entirely according to your individual

requirements.

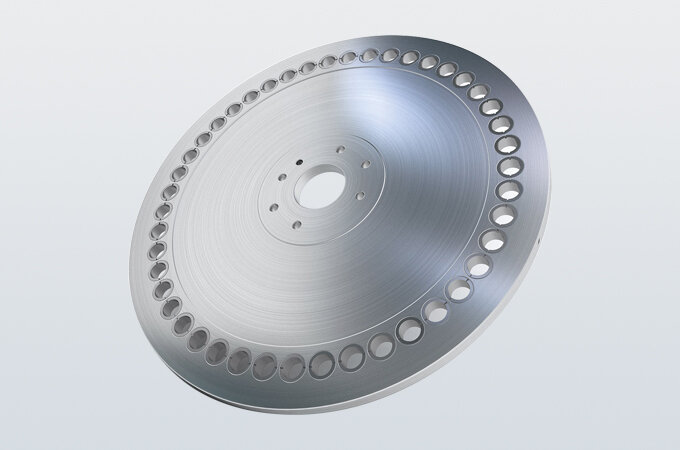

Bearing Rails

Support Shels

Grinding Stars

Products

Through-Feed Blades

These work rest blades are used for workpieces whose diameter needs to be ground uniformly.

Prism Blades

These work rest blades are primarily used in

through-feed grinding. For the workpiece, the

prismatic guide of the prism blade (usually

120°, carbide-tipped on both sides) ensures

a simple and clean feed to and removal from

the grinding process. However, the workpiece

is lifted from the prism during the grinding

process, and is in contact with the blade

only on one side, i.e. the side of the grinding

wheel.

Plunge Cut-/ Stepped Blades

These blades are used for workpieces whose

diameter needs to be ground uniformly, but

cannot be through-feed ground (component-

wise with projection or the like).

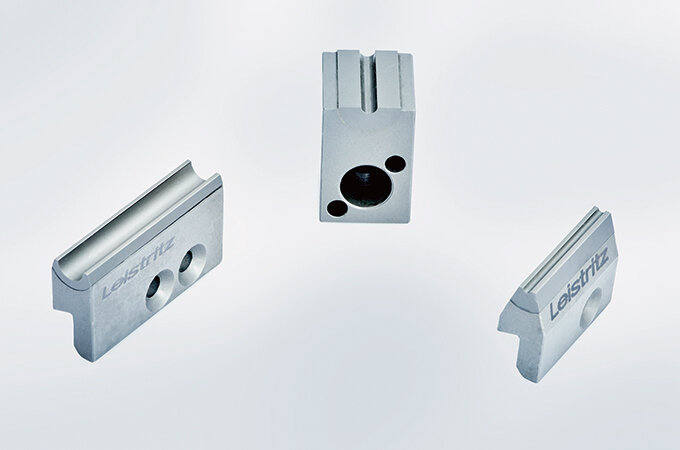

Screwed Blades

Example of a through-feed blade in screw

version with clamping plate for customer-exchangeable

hard metal.

Corrugated Blades

These blades stabilize the blade body with

low A-dimensions < 1.0 mm in the grinding

process. The regulating wheel must be

adjusted accordingly.

Customized Solutions

A particular challenge are work rest blades

for barrel-shaped workpieces. This example

is used for through-feed grinding with a 30°

inclination.

Soon you can configure your individual tool, using our product configurator

We are here for you

You have any questions about our solutions? Your personal contact person looks forward to hear from you!

Andy Sperber

Customer Service

Leistritz Produktionstechnik GmbH

T+49 (9654) 89-283