Turning is by far the most traditional form of machining. We have looked at this area from the perspective of the highest possible productivity. We will find the technically most suitable solution for almost every task.

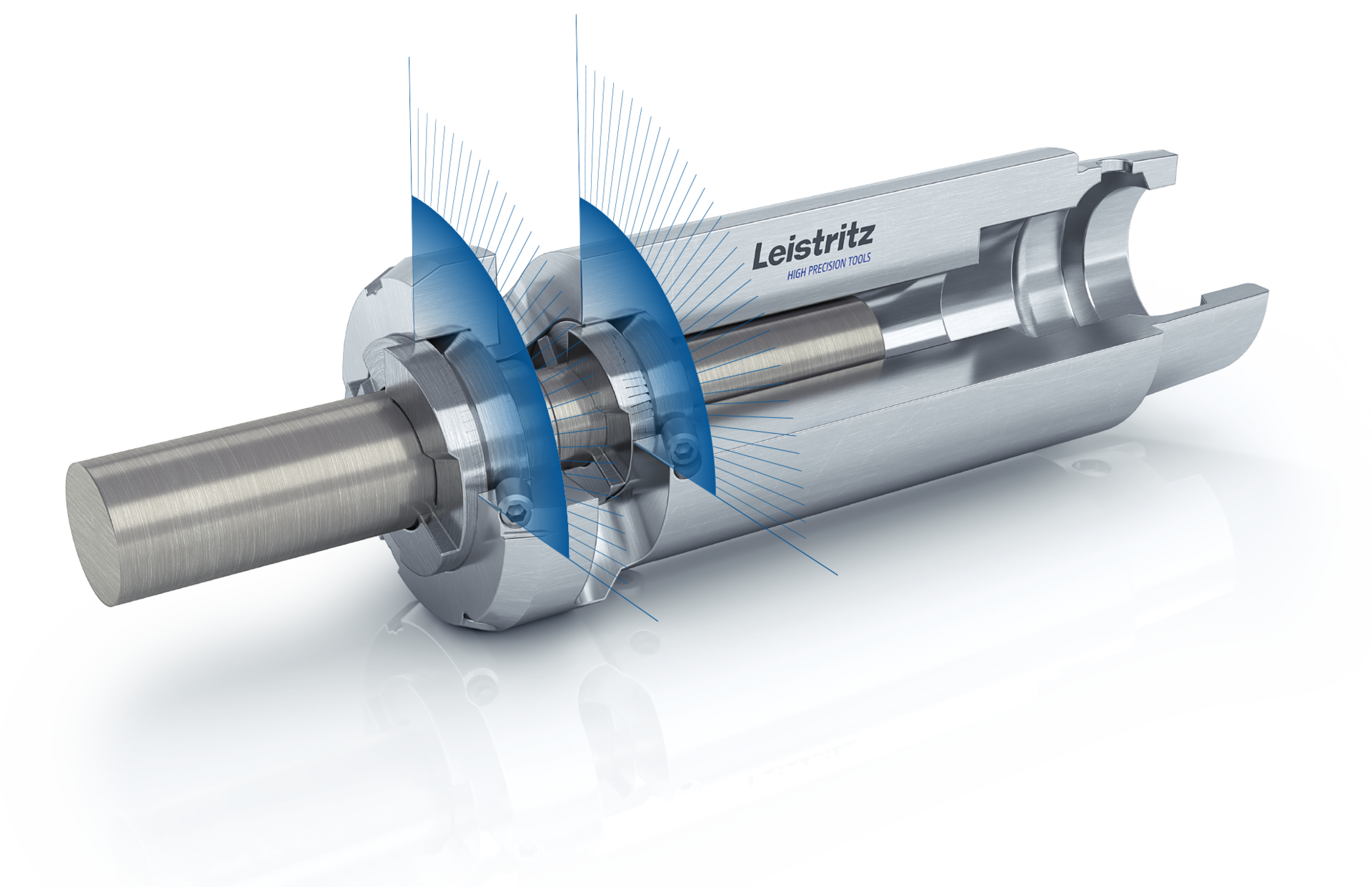

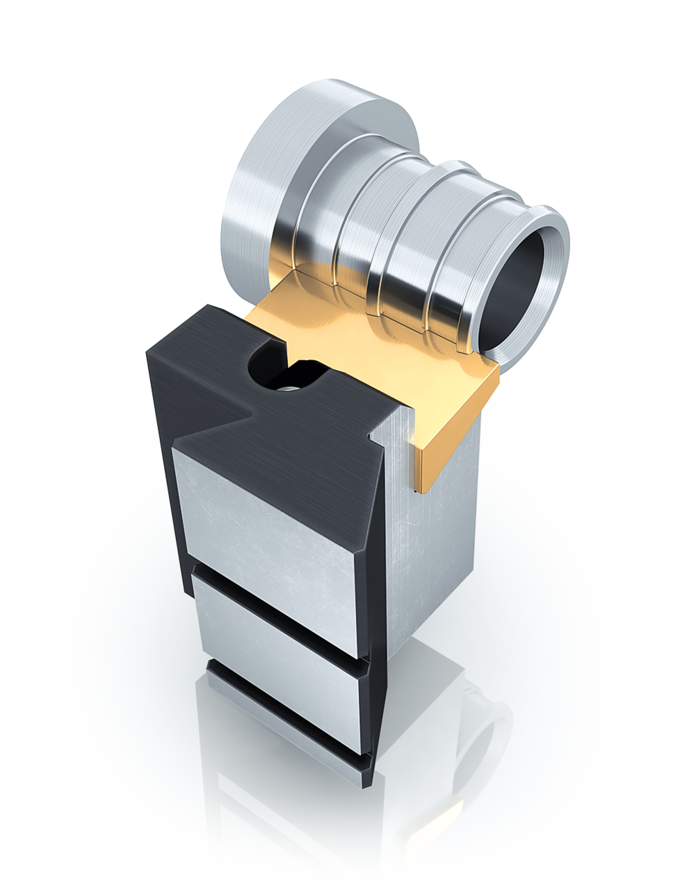

The new dimension of turning. OverCut.

Axial turning with multiple diameters

- Cost- and time-saving multifunctional tool

- Manufacture up to 6 x faster

- Several production steps in one operation

No radial displacement

Due to the radialy arranged cutting inserts, the force is evenly distributed on the workpiece.

Exchangable cutting inserts

The cutting inserts can be changed to suit the application. This means that you are always well prepared for changes.

One body for everything

With only one basic body a wide range of diameters can be machined.

Sufficiant Cooling

The Leistritz OverCut is available with internal coolant supply. The chips are flushed out, the tool life of the tool inserts is ultimately considerably increased.

Quality

The well-known Leistritz quality enables maximum tool life and process reliability

Reconditioning

Not new, but just like new: With reconditioning in original equipment quality, we offer an absolutely economical solution.

Process Analysis

Our experts analyse your current process with you and develop the optimal tool from it.

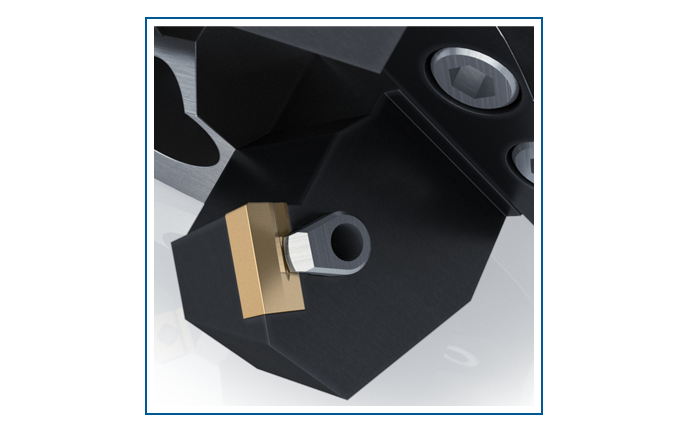

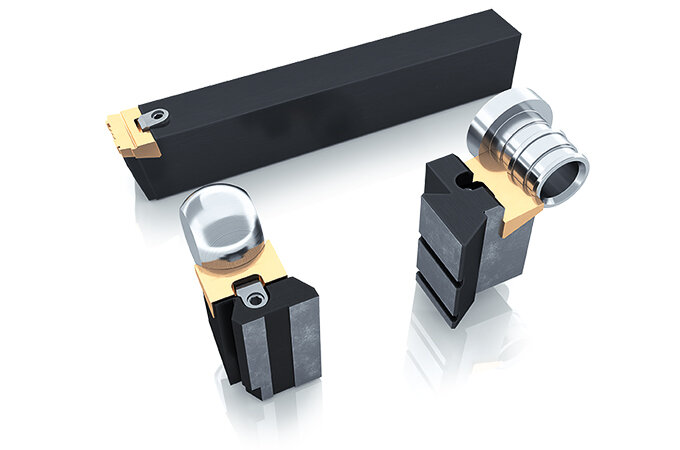

The pacemaker for a perfect end

Up to 5 steps in one

- Complete supplier: Inserts and tool bodies in special

and standard design can be freely combined - Short delivery times

Highest economic efficiency

By using profile inserts, even complex shapes can be machined.

Exchange accuracy

The insert seat grinding enables easy excahnge.

Outstanding stability

The cutting pressure is applied over the entire width of the insert, and thus enables optimum force transmission.

Quick change saves time

The Leistritz clamping system allows the profile inserts to be changed inside and outside the machine.

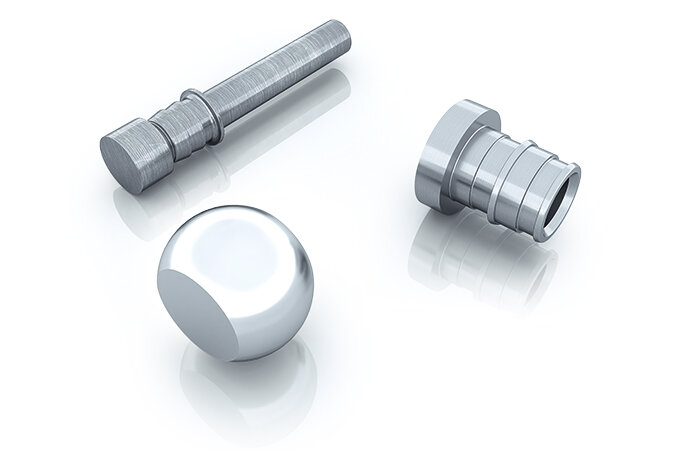

Profiling

Complex turned part contours require high-performance profile cutting tools for the economical production of these turned parts. At the Leistritz Profile Centre, we will be happy to take care of the profile design and cutting layout for you on request.

INDIVUDUAL INSERTS

FROM WORKPIECE

TO TOOL

Products

Overcut

- no radial displacement of the workpiece

- shorter machining time due to a higher feed rate

- interchangeable blade set

- different diameters can be used in one basic body

- higher surface quality

- longer service lives

- optionally available with internal coolant supply (ICS)

End finishing tools

- up to 5 working operations in one operation

- different workpiece diameters machined with the same tool, as these are radially adjustable

- easy adjustment of the tools

- flexible tooling thanks to a modular system

- tool heads, insert holders and adapters are available from stock

- tool is adaptable to all machines

End finishing tools mini

All the advantages of Leistritz end finishing tools for small diameters

Tube chamfering inserts

We profile your tube-chamfering insert for you!

- from inner tube - Ø 4 mm

- wall thickness 0.8 - 2 mm

- radii and special designs possible

Top Turn

The perfect end finishing of workpieces with a diameter of 1 mm or more.

The innovation lies in the special cutting edge geometry of the form inserts. Whether classic facing

and chamfering, or a specific profile contour – many things can be manufactured in just one operation.

Soon you can configure your individual tool, using our product configurator

We are here for you

You have any questions about our solutions? Your personal contact person looks forward to hear from you!

Andy Sperber

Customer Service

Leistritz Produktionstechnik GmbH

T+49 (9654) 89-283