Convincing precision

As a manufacturer of precision tools, we have decades of experience in the design and manufacture of special tools. We have adapted our delivery program mainly to the turning of workpieces (end machining, profile turning, recess turning, thread turning and general turning) as well as to the further processing of turned parts (grinding supports for centerless grinding). Here we show an excerpt from our tool program.

The perfect fit for your machining task

Our LeistritzPerformanceTools (LPT) can be found in the standard program as LPTline. These tools are of course available from stock.

You have individual wishes regarding dimensions, material, tipping, coating? With pleasure! In our LPT+line we manufacture your individual

request according to your drawing.

LPT – the new synonym for "efficiency".

Fast and easy with LeistritzPerformanceTools

Your challenge – Our high precision cutting tool. The perfect combination for your production.

Sometimes established tool solutions are needed. Sometimes you may have to rethink and take up new ideas. Our claim is to combine both approaches – of course only where it makes sense and both productivity and cost-effectiveness can be increased. Depending on the production task, we combine

the tried and tested with (customized) innovations for you.

On the following pages you will find our standard tools as well as high-end solutions. Let us inspire you!

We look forward to your challenge!

Stefan Kühnle

Vice President Tooling

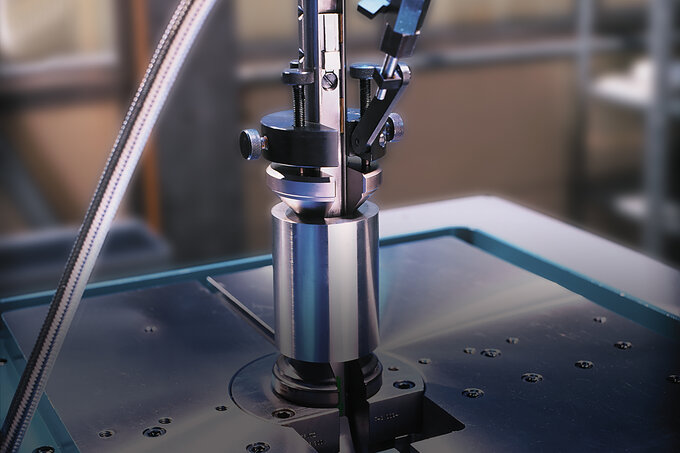

Grinding

High-precision grinding of rotationally symmetrical components is a common way of manufacturing in many industries – both with and without a supporting element.

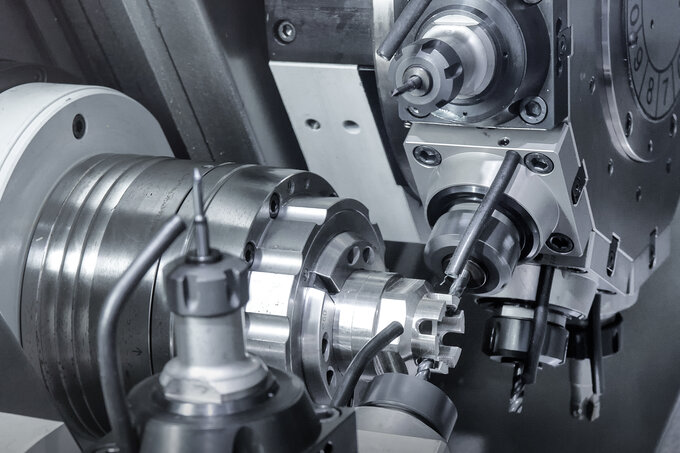

Turning

Turning is by far the most traditional form of

machining. We have looked at this area from the perspective of the highest possible productivity.

Drilling

Drilling is the most common type of machining in the machining industry. We have taken up this topic and have put together a programme that offers the perfect solution for many applications.

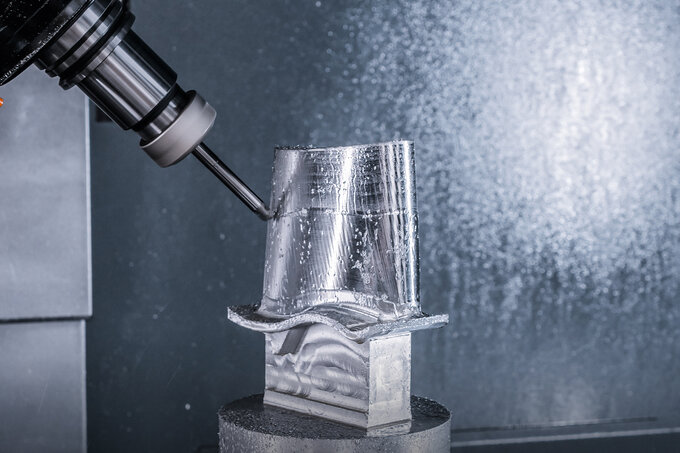

Milling

The production of complex parts requires sophisticated tools! High process reliability, tool life and surface quality are particularly important in milling. With Leistritz solid carbide milling cutters, we have the right tool for your machining task.

Keyseating

Keyseating offers you a quick and accurate

alternative to broaching and shaping.

Thanks to our many years of experience in

the construction of keyseating machines, we

have comprehensive application knowledge.

Construction – replacement – regrinding,

everything is covered with our portfolio.

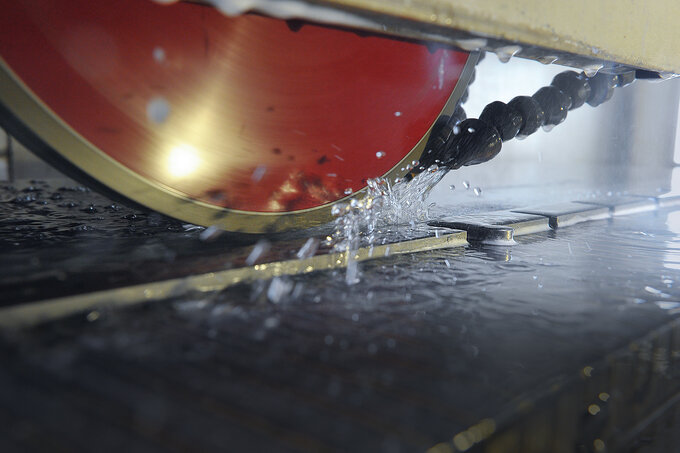

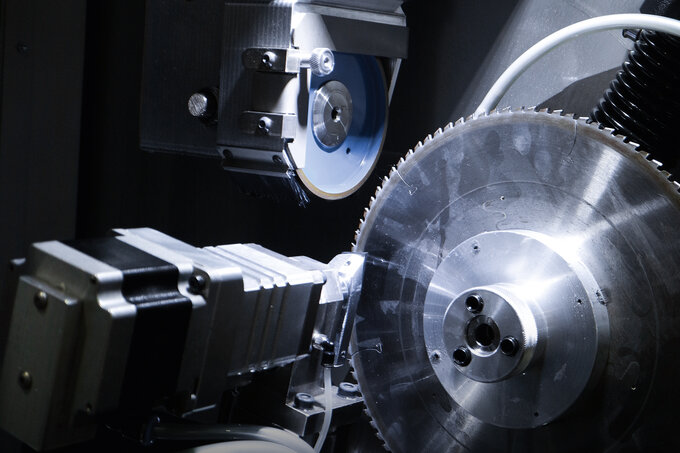

Sawing

Industrial sawing involves a number of pitfalls.

Who could be a better partner at your side than

the experts for metalworking of any kind? With

our broad expertise in machining processes, we

are also there for you in the area of sawing. And

with our regrinding service, your saw blades will

stay in use for longer.

Laboratory Equipment

Highest laboratory quality – mass produced. With our microtome knives, you get a high-precision solution, without the need for

further processing steps, such as polishing. We are your partner from design to assembly.

Reconditioning

Not new, but just like new: With reconditioning in original equipment quality, we offer an absolutely economical solution.