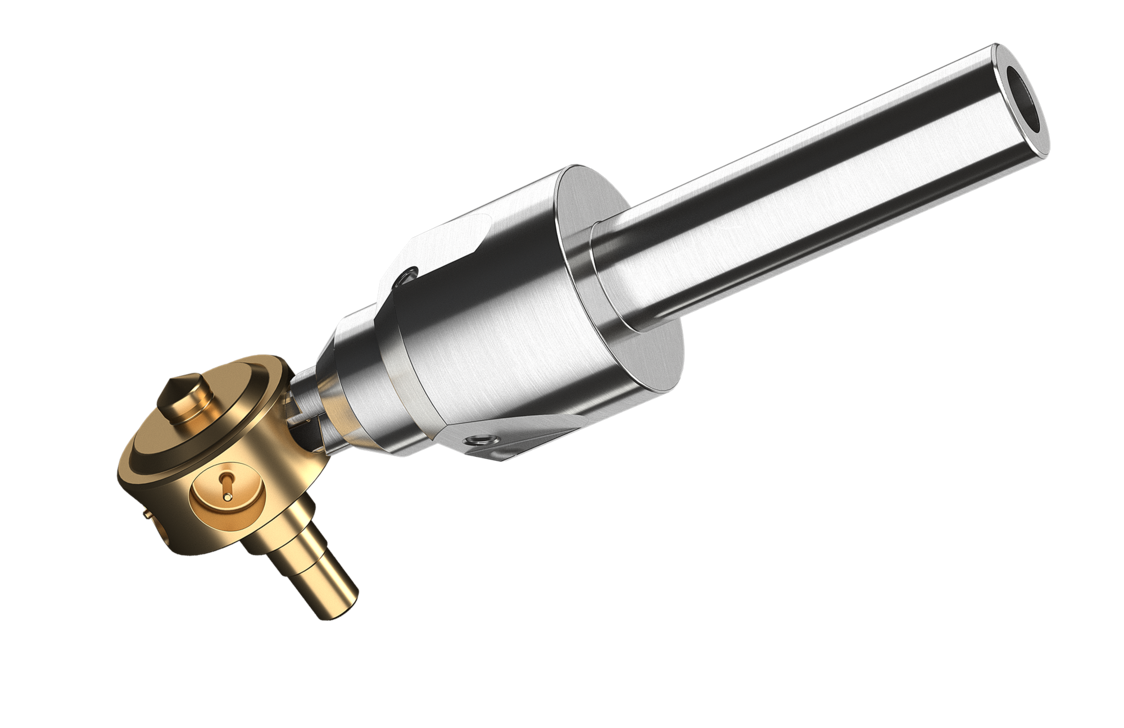

Everyone talks about Plug & Play -

we just make it happen with the new OverCut-PIN!

We upgrade our portfolio and you change tools – all within a very short period of time. Two to three hours for a tool change? A matter of the past with the OverCut-PIN. With our new super tool for processing workpieces, you not only change over within ten minutes; you also save time and money by mapping complex part contours with just one tool.

More productivity. More quality. Less costs.

Leistritz OverCut-PIN

Our goal?

To produce multiple features in the smallest parts sector economically and reliably with one tool.

Our result:

A completely new type that clearly pushes the limits of what is possible.

Individual design option per insert or regrindable as a set.

Machine connection adaptable or direct.

Optimal precision clamping for component tolerances > 0.01mm.

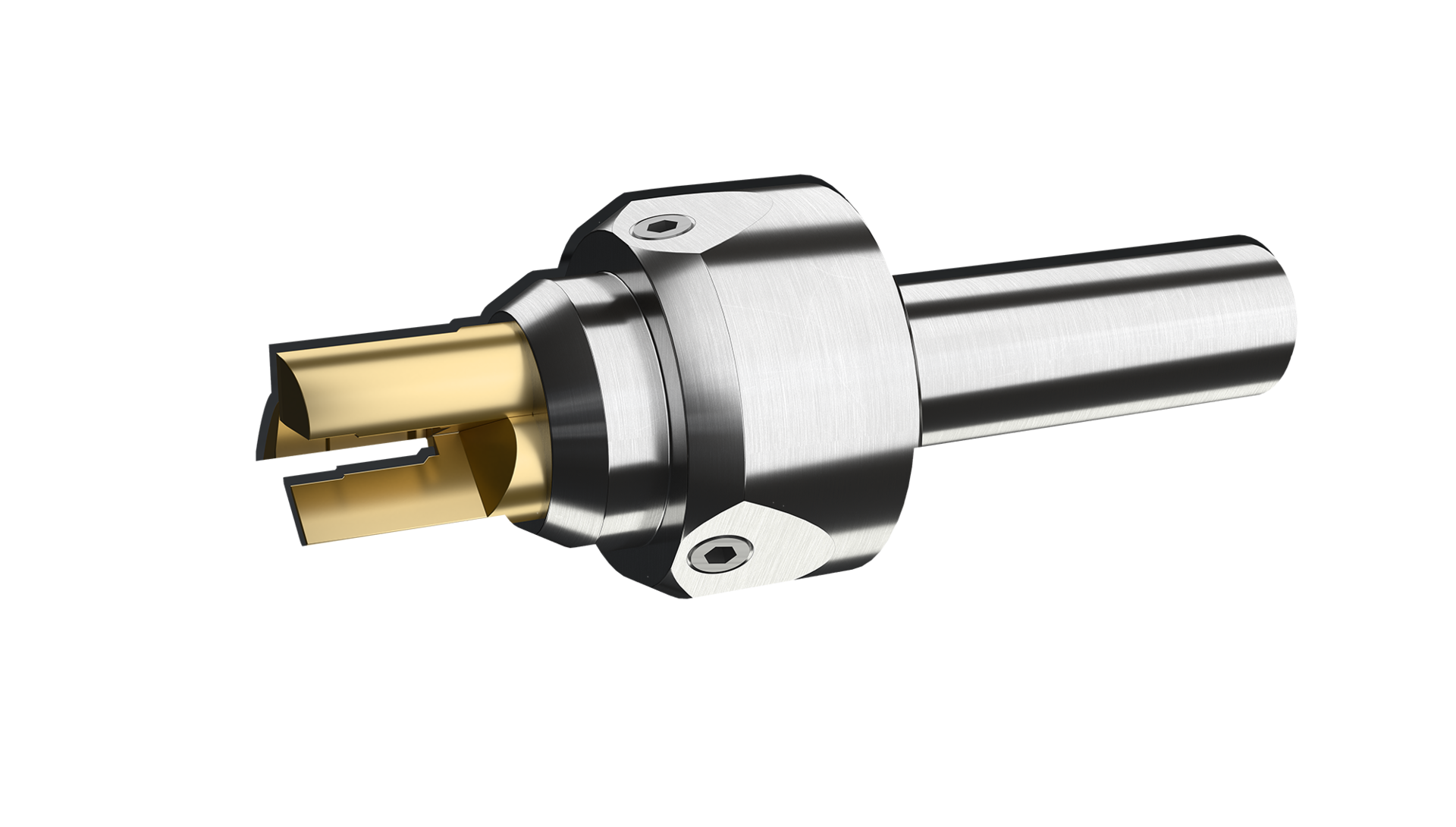

Facts at a glance

- Tool for external and internal machining

- Cylindrical workpieces without displacement

- Applicable on all machine types (adapter)

- Outer diameter of 0,8mm-10mm producible

- Inner diameter of 5,0mm-10mm producible

- Optimum workpiece surface and chip control thanks to internal coolant supply

- Full process control thanks to simple traversing movement on the machine

- Contour profile on one or more cutting edges (up to 15mm depth)

- Simplest programming

- Reduced setup time and number of tool places

Our portfolio

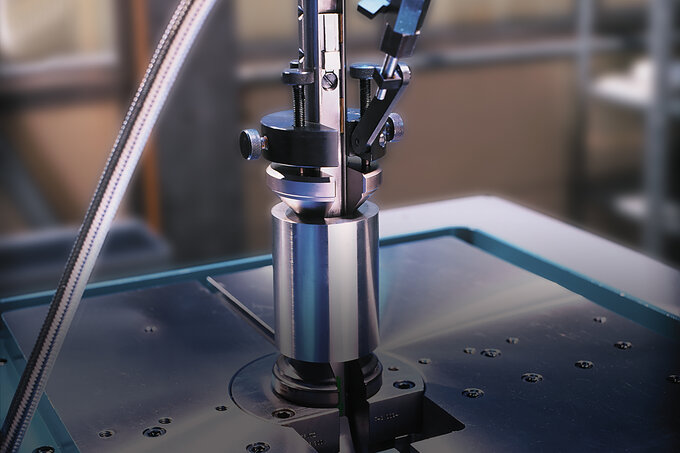

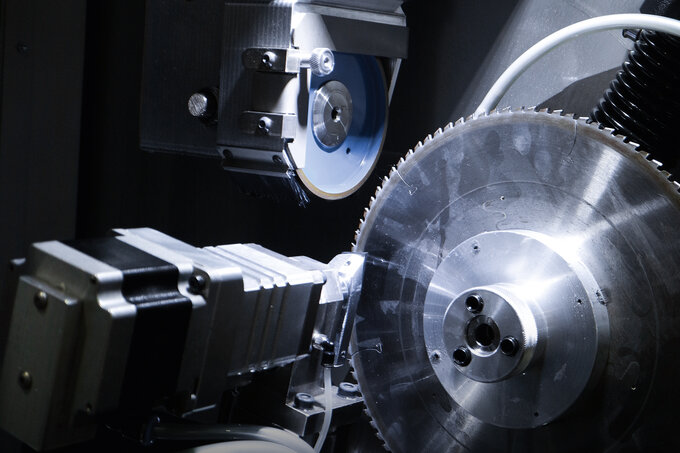

Grinding

High-precision grinding of rotationally symmetrical components is a common way of manufacturing in many industries – both with and without a supporting element.

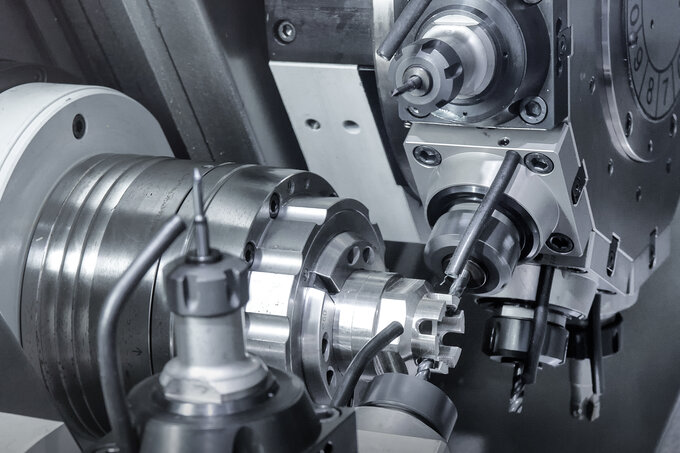

Turning

Turning is by far the most traditional form of

machining. We have looked at this area from the perspective of the highest possible productivity.

Drilling

Drilling is the most common type of machining in the machining industry. We have taken up this topic and have put together a programme that offers the perfect solution for many applications.

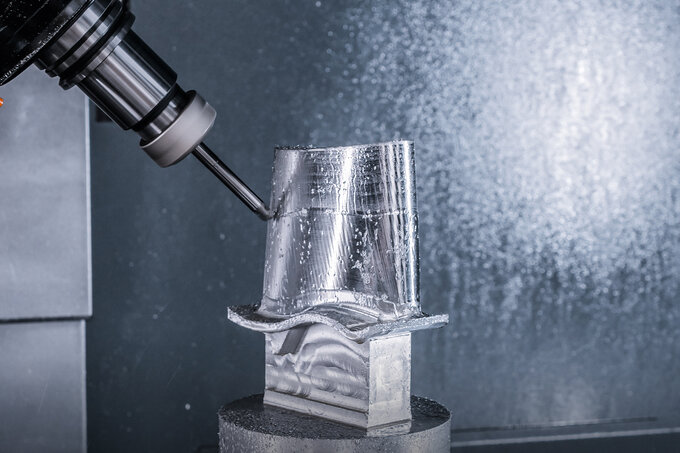

Milling

The production of complex parts requires sophisticated tools! High process reliability, tool life and surface quality are particularly important in milling. With Leistritz solid carbide milling cutters, we have the right tool for your machining task.

Keyseating

Keyseating offers you a quick and accurate

alternative to broaching and shaping.

Thanks to our many years of experience in

the construction of keyseating machines, we

have comprehensive application knowledge.

Construction – replacement – regrinding,

everything is covered with our portfolio.

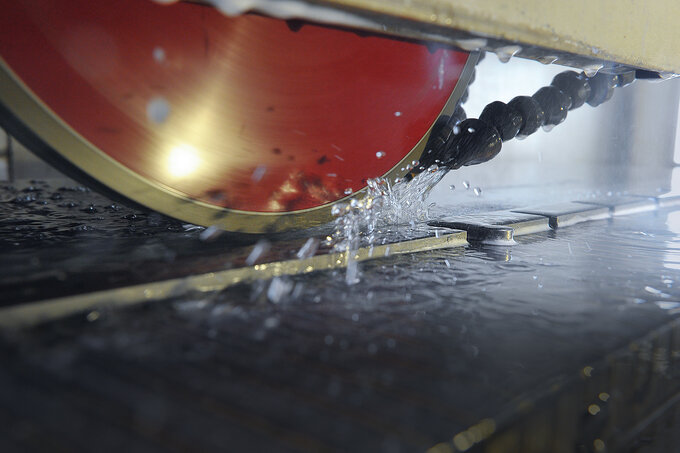

Sawing

Industrial sawing involves a number of pitfalls.

Who could be a better partner at your side than

the experts for metalworking of any kind? With

our broad expertise in machining processes, we

are also there for you in the area of sawing. And

with our regrinding service, your saw blades will

stay in use for longer.

Laboratory Equipment

Highest laboratory quality – mass produced. With our microtome knives, you get a high-precision solution, without the need for

further processing steps, such as polishing. We are your partner from design to assembly.

Reconditioning

Not new, but just like new: With reconditioning in original equipment quality, we offer an absolutely economical solution.

Markus Fuchs

Head of Customer Service

Leistritz Produktionstechnik GmbH